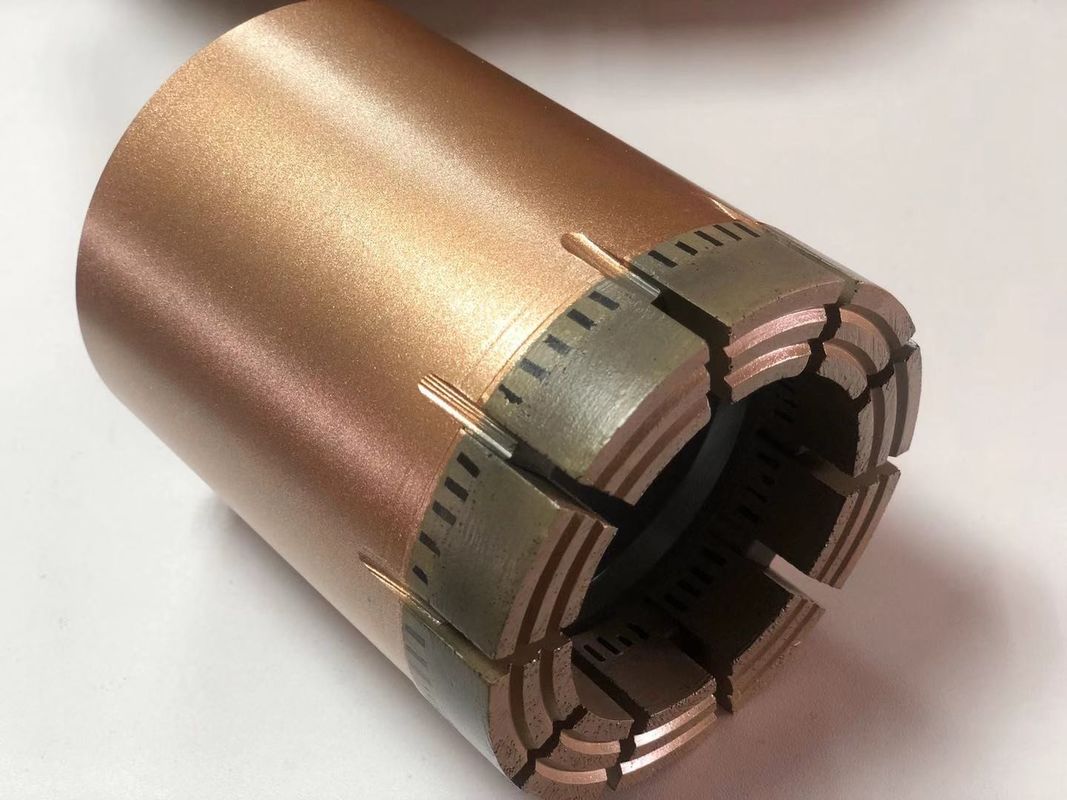

12mm HQ Impregnated Diamond Core Drill Bits DCDMA Standard with CE certification

SINOCOREDRILL impregnated diamond bits are manufactured using high quality raw materials for optimum drilling performance. As a result of our personnel's more than 40 years of experience in the drilling Industry,We can recommend the optimum design for optimum performance in a variety of applications and conditions. Various face profiles, bonds and diamond qualities are available for superior coring performance and longer bit life resulting in fewer trips in and out of the hole, reducing costs and improving production.

1. ISO9001certificated

2. 10years manufacturing experience

3. Super antiwear characteristic

4. Super long lifetime

5. Solid quality

The impregnated diamond bits are the most commonly useful bits in the mineral exploration industry, as they have the widest range of application. The carefully selected grades of high quality synthetic diamond are distributed in the depth of impregnated bit's matrix series. The matrix layer of the ZM contains a uniform distribution of these crystals that are embedded in a powdered metal bond.

The matrix of our impregnated bits is designed to expose new diamonds to the bits cutting face as wear occurs. Fast penetration rate is maintained as a result of this action.

Our impregnated bits are manufactured to give optimum penetration rates and bit life, which is required to keep the cost of diamond drilling to a minimum.

| Q series core bits |

| Size |

O.D |

I.D |

Availability |

| mm |

mm |

Imp. |

S.S |

T.C. |

PDC |

TSP |

E.P. |

| AQ |

47.75/47.50 |

27.10/26.85 |

√ |

√ |

√ |

√ |

√ |

√ |

| BQ |

59.69/59.44 |

36.52/36.27 |

√ |

√ |

√ |

√ |

√ |

√ |

| BQ3 |

59.69/59.44 |

33.65/33.40 |

√ |

√ |

√ |

√ |

√ |

√ |

| NQ |

75.44/75.19 |

47.75/47.50 |

√ |

√ |

√ |

√ |

√ |

√ |

| NQ3 |

75.44/75.19 |

45.21/44.96 |

√ |

√ |

√ |

√ |

√ |

√ |

| HQ |

95.76/95.38 |

63.63/63.38 |

√ |

√ |

√ |

√ |

√ |

√ |

| HQ3 |

95.76/95.38 |

61.24/60.99 |

√ |

√ |

√ |

√ |

√ |

√ |

| PQ |

122.30/121.80 |

85.09/84.84 |

√ |

√ |

√ |

√ |

√ |

√ |

| PQ3 |

122.30/121.80 |

83.18/82.93 |

√ |

√ |

√ |

√ |

√ |

√ |

| Core bits for N-series double core barrels |

| NMLC |

75.44/75.19 |

52.12/51.87 |

√ |

√ |

√ |

√ |

√ |

√ |

| HMLC |

98.98/98.60 |

63.63/63.38 |

√ |

√ |

√ |

√ |

√ |

√ |

| Core bits for T2 series double core barrels |

| T2-46 |

46.18/45.92 |

31.82/31.57 |

√ |

√ |

√ |

√ |

√ |

√ |

| T2-56 |

56.13/55.88 |

41.83/41.58 |

√ |

√ |

√ |

√ |

√ |

√ |

| T2-76 |

76.12/75.87 |

61.82/61.57 |

√ |

√ |

√ |

√ |

√ |

√ |

| T2-86 |

86.13/85.88 |

71.83/71.58 |

√ |

√ |

√ |

√ |

√ |

√ |

| T2-101 |

101.12/100.87 |

83.82/83.57 |

√ |

√ |

√ |

√ |

√ |

√ |

| Core bits for T6 series double core barrels |

| T6-76 |

76.12/75.87 |

57.12/56.87 |

√ |

√ |

√ |

√ |

√ |

√ |

| T6-86 |

86.13/85.88 |

67.13/66.88 |

√ |

√ |

√ |

√ |

√ |

√ |

| T6-101 |

101.12/100.87 |

79.12/78.87 |

√ |

√ |

√ |

√ |

√ |

√ |

| T6-116 |

116.20/115.82 |

93.14/92.89 |

√ |

√ |

√ |

√ |

√ |

√ |

| T6-131 |

131.19/130.81 |

108.13/107.88 |

√ |

√ |

√ |

√ |

√ |

√ |

| T6-146 |

146.18/145.80 |

123.11/122.86 |

√ |

√ |

√ |

√ |

√ |

√ |

| Core bits for Chinese standard single tube core barrels |

| 59 |

59.5 |

41.5 |

√ |

√ |

√ |

√ |

√ |

√ |

| 75 |

75.2 |

54.5 |

√ |

√ |

√ |

√ |

√ |

√ |

| 91 |

91.2 |

68 |

√ |

√ |

√ |

√ |

√ |

√ |

| 110 |

111.2 |

93 |

√ |

√ |

√ |

√ |

√ |

√ |

| 130 |

131.2 |

113 |

√ |

√ |

√ |

√ |

√ |

√ |

| 150 |

151.2 |

133 |

√ |

√ |

√ |

√ |

√ |

√ |

| 170 |

171.2 |

149 |

√ |

√ |

√ |

√ |

√ |

√ |

| 219 |

225.2 |

197 |

√ |

√ |

√ |

√ |

√ |

√ |

| Core bits for Chinese standard double tube core barrels |

| 75 |

75.2 |

54.5 |

√ |

√ |

√ |

√ |

√ |

√ |

| 91 |

91.2 |

68 |

√ |

√ |

√ |

√ |

√ |

√ |

| 110 |

111.2 |

93 |

√ |

√ |

√ |

√ |

√ |

|

Noted:

Imp.-Impregnated Diamond Type

S.S.-Surface Set Diamond Type

T.C.-Tungsten Carbide Type

PDC.-Polycrystalline Diamond compact Type

E.P.- Electroplated Diamond Type

Advantages:

1.Fast cutting and drilling speed

2.Long life, stable performance

3.Low power consumption

4.Professional OEM, superior grade quality, more than 5years manufacturing experience

5..CE: ISO: 9001: 2000

Warranty and Service

We always concerned about our clients and provides them with warranty and service support.

The factory ensures equipment warranty for the major assemblies and units efficient for 12 months. The clients are supplied with all needed spare parts, tooling and auxiliary facilities.

The authorized dealers possess service centers to execute product warranty liabilities, after-sales service and equipment repair. The clients’ staff is also provided with theoretical and practical company instructions and consultations on all matters concerning execution of work and equipment operation.

Q:Are you trading company or manufacturer ?

A: We are a specialized manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

T/T, L/C, Western Union.

Q: What are your main products, and used for?

A: Our products include core bit, PDC bit, reaming shell, core barrel, casing, drill rod, drill rig and other drilling parts.

They are used for mineral exploration, geological drilling, geotechnical engineering and soil sampling.

Q: How about the delivery terms?

A: Min. order quantity: 1 piece. Transportation: By DHL/TNT/Fedex express, air, sea, train.

Q: How about discount?

A: Price is based on products and order quantity.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How about your after-sales service?

A: As a manufacturer, we offer promote technology support for all problems and questions. Besides, we accept goods return or replace for quality problem.

Q: Where is your factory located in?

A: Our factory is located in Jiangyin city,Jiangsu province, China.

Q: How does your company control the quality?

A: Quality first. In order to guarantee high quality for our products, Sinocoredrill usually makes a serious inspection for all products and raw materials in strict procedure

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!