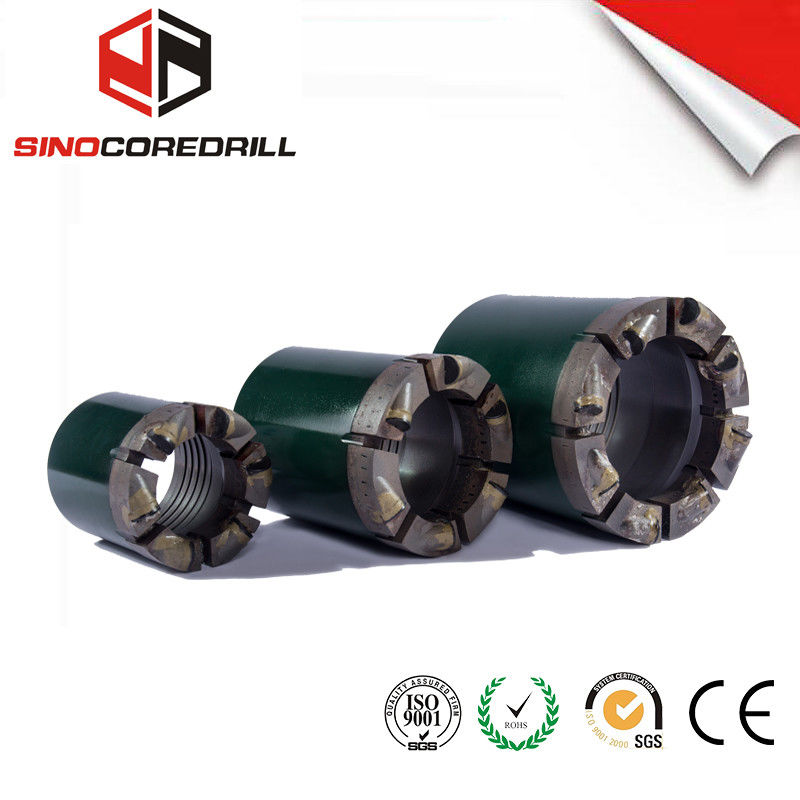

PCD NQ HQ PQ Polycrystalline Compact Diamond Bits

PCD NQ HQ PQ Polycrystalline Compact Diamond PDC Diamond Drill Bits

Description:

The PDC bit is short for polycrystalline compact diamond bits. It is made up of tough, anti-friction matrix and gauge reinforcement. The PDC coring bit is suitable in homogeneous soft to medium sedimentary forms.

Features:

1.There are several sizes of PDC cutters with high productivity and long service life.

2.Wearing cutters can be replaced to be utilized again.

3.PDC coring bits are of all standard drilling sizes and many region-specific sizes.

Specifications:

PDC Drill Bit

This PDC drill bit is a fixed pattern with a designed type of matrix on the top and equipped with natural diamonds on both sides. There are two types of the PDC drill bits: coring and non-coring drill bits. They are used to drill coal, gas and oil in soft to medium hard forms. The PDC drill bits consist of: 28mm, 32mm, 42mm, 45mm, 48mm, 56mm, 65mm, 76mm, 85mm, 96mm, 99mm, 114mm, and 123mm. The thread is NW male thread. Samples are available.

PDC Coring Bit

It is applied in coal exploration from soft to medium hard forms. The PDC coring bits include: AQ, BQ, BQ3, NQ, NQ3, NQTT, HQ, HQ3, HQTT, PQ, PQ3, and PQTT.

PDC Drill Bit

This PDC drill bit is also used in coal exploration from soft to medium forms as a base drilling. The PDC coring bits contain HWF, 412, PWF, SWF, NQ3, HQ3, NQTT, HQTT, PQ3, and PQTT of the face discharged.

Wireline core drilling products:

Geological Core Bits:

Impregnated Bit(T2-76/86/101,etc; BQ,HQ,NQ,PQ,etc)

Surface Bit(T2-76/86/101,etc; BQ,HQ,NQ,PQ,etc)

Reaming Shell(T2-76/86/101,etc; BQ,HQ,NQ,PQ,etc)

Core Barrels & spare parts:

core lifters, core lifter cases, stop rings, landing rings, landing shoulders, inner tube stabilizers, locking couplings, adaptor couplings,

inner tube and outer tubes wrenches, head assembly, Core Barells,

Warranty and Service

We always concerned about our clients and provides them with warranty and service support.

The factory ensures equipment warranty for the major assemblies and units efficient for 12 months. The clients are supplied with all needed spare parts, tooling and auxiliary facilities.

The authorized dealers possess service centers to execute product warranty liabilities, after-sales service and equipment repair. The clients’ staff is also provided with theoretical and practical company instructions and consultations on all matters concerning execution of work and equipment operation.

Q:Are you trading company or manufacturer ?

A: We are a specialized manufacturer.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

T/T, L/C, Western Union.

Q: What are your main products, and used for?

A: Our products include core bit, PDC bit, reaming shell, core barrel, casing, drill rod, drill rig and other drilling parts.

They are used for mineral exploration, geological drilling, geotechnical engineering and soil sampling.

Q: How about the delivery terms?

A: Min. order quantity: 1 piece. Transportation: By DHL/TNT/Fedex express, air, sea, train.

Q: How about discount?

A: Price is based on products and order quantity.

Q: Do you accept sample order?

A: Yes sure, please contact us for details.

Q: How about your after-sales service?

A: As a manufacturer, we offer promote technology support for all problems and questions. Besides, we accept goods return or replace for quality problem.

Q: Where is your factory located in?

A: Our factory is located in Jiangyin city,Jiangsu province, China.

Q: How does your company control the quality?

A: Quality first. In order to guarantee high quality for our products, Sinocoredrill usually makes a serious inspection for all products and raw materials in strict procedure

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!