500-600m Modular Drill Rigs Lightweight Portable Core Drilling With Hydraulic Drive

EP600 is one of the best-selling rigs known for its stability, quality and cost-efficiency and outstanding performance. It is easy to operate and is designed for 200-700 meters deep hole projects in hard-to-access areas and complex land formations. EP600 has been widely used in many areas and can be used together with the self-propelled crawler module and horizontal drilling frame.

Various module combinations available for drilling rigs’ different requirements

1, Crawler Self-Propelled Drilling Rig

2, Horizontal Drilling Frame Module

3, Asynchronous motor module

Modularized with mast drilling frame

Lightweight design with the heaviest module weighting less than 180Kg; does not require road construction and manpower

Mast drilling frame that can be easily transported and disassembled; does not require drilling s

Top-drive power heads; long-way guide rail; push by oil cylinders; does not require repeated rechucks Operated in small area; does not require foundation construction

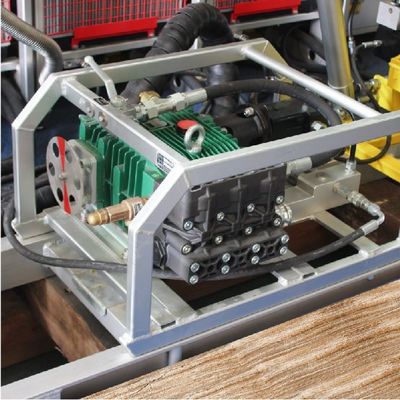

Fully hydraulic transmission

Flexible and lightweight design for easy operation

Steady drilling with adjustable and high speed

Real-time over-pressure protection provided

They are widely used for geological exploration engineering as below:

1. Geological mineral exploration;

2. Mineral exploration for drilling in place of trenching

3. Geological disaster governance and exploration

Comparison of Traditional Drilling Rigs with Portable Full Hydraulic Core Drilling Rigs

| NO. |

Traditional Drilling Rigs |

Portable Full Hydraulic Core Drilling Rigs |

| 1 |

Integral structure, bulky |

Modular construction, lightweight |

| 2 |

Need to build roads, mechanized relocation |

No need to build roads, manual road handling |

| 3 |

Mechanical transmission |

Fully hydraulic Transmission |

| 4 |

Four-corner drill tower, high-altitude operation hazard |

Mast-type drill frame, light and safe |

| 5 |

Card plate and active drill pipe, low speed, vibration, repeated guide rod damage hole wall, resulting in frequent accidents in the hole |

Top drive power head, high speed and smooth |

| 6 |

Large area and damage to the environment |

No digging machine, environmentally friendly |

| 7 |

General drilling technology, poor quality, low efficiency |

Thin-walled rope heart-taking process, good quality, efficient. |

| 8 |

Low rate of core adoption, poor quality |

High rate of core adoption, good quality |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!